Understanding Metal Laser Cutter in 5 Minutes

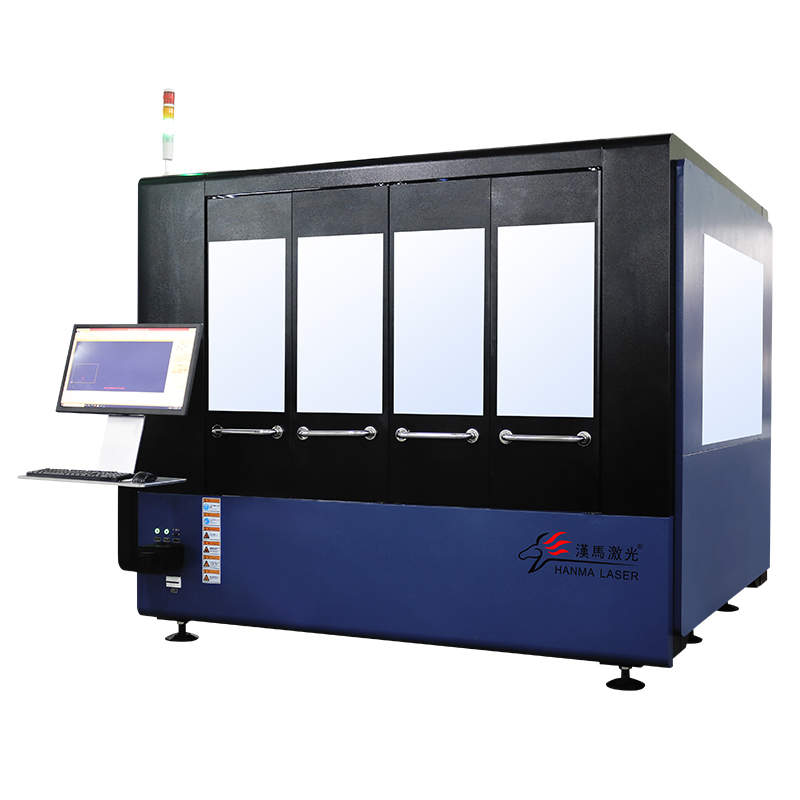

A laser cutter is a machine that uses a laser to cut materials. While typically used for industrial manufacturing applications, it is also starting to be used by schools, small businesses, and hobbyists.

Laser cutting works by directing the output of a high-power laser most commonly through optics. The laser optics and CNC (computer numerical control) are used to direct the material or the laser beam generated.

A typical commercial laser for cutting materials would involve a motion control system to follow a CNC or G-code of the pattern to be cut onto the material.

The focused laser beam is directed at the material, which then either melts, burns vaporize away, or is blown away by a jet of gas, leaving an edge with a high-quality surface finish.

Industrial laser cutters are used to cut flat-sheet material as well as structural and piping materials. The process is most often used in industrial manufacturing with metals and plastics.

In addition to cutting materials with lasers like stainless steel, aluminum, titanium, and other metals, it can also be used on extremely thin materials such as foils (0.001 inches in thickness), paper, plastics, and textiles such as silk and cotton.

Moreover, metal laser cutters have many benefits. They are highly accurate, able to make clean cuts that do not require further finishing. They are also incredibly fast and efficient, with some machines able to cut up to 30 meters per minute.

Conclusion:

A metal laser cutter is a machine that uses a CO2 laser to cut metals. The laser beam is highly focused and concentrated, so it can deliver high-quality cuts. The metal laser cutter can cut through a wide range of thicknesses and types of metal, including aluminum, steel, stainless steel, etc.