Metal Laser Cutting Advantages

If you want to cut metal parts, you should know the benefits of metal laser cutting. These include low power consumption, maintenance free and precise cutting. Read on to learn more. This article will help you decide if laser cutting is right for your project. It will also help you choose the right machine.

Low power consumption

If you are looking for a machine that can cut sheet metal at low power, you should consider a CO2 laser. This type of laser is known for its high energy, low repetition and low power consumption. Typical applications for such lasers are metal sheets and ceramics. They are solid-state devices with a small spot size, making them ideal for cutting reflective metals.

The quality of metal laser cutting depends on several factors, including the frequency and power of the laser radiation, the initial burn, and the time delay between successive cuts. For example, a thick piece of metal requires a higher power laser to achieve the same effect. In addition, high power lasers are required to cut metals with higher reflectivity.

Maintenance free

There are several benefits to using metal laser cutting equipment compared to traditional manufacturing methods. By following a few simple maintenance procedures, manufacturers can ensure their laser cutting equipment is performing at peak performance and efficiency. In addition, they can benefit from a service contract that provides regular preventive maintenance advice.

Regularly check the air lines of the metal laser cutting machine. Your machine needs clean, filtered air to maintain high cutting performance. Most manufacturers publish recommended maintenance guidelines. You should perform monthly inspections to keep compressed air lines free of rust, water, and contamination. Airborne debris can affect cutting performance and reduce machine life. It is also important to use a dedicated compressor to run the laser cutter. This will prevent other processes from using the same air source.

Fiber laser cutting machines are essential equipment for metalworking workshops. It can perform functions that humans cannot. However, if the machine fails, it will take a long time to fix. This slows down production and requires downtime. Therefore, regular maintenance of your metal laser cutting machine will help you save money and time.

Precise cut

Metal laser cutting is a versatile technique that produces clean, precise cuts. From small parts to industrial-sized sheet metal, metal laser cutting offers a wide range of cutting applications. Its high precision allows the production of complex shapes and designs with minimal material waste. This process is especially useful for projects that require tight tolerances.

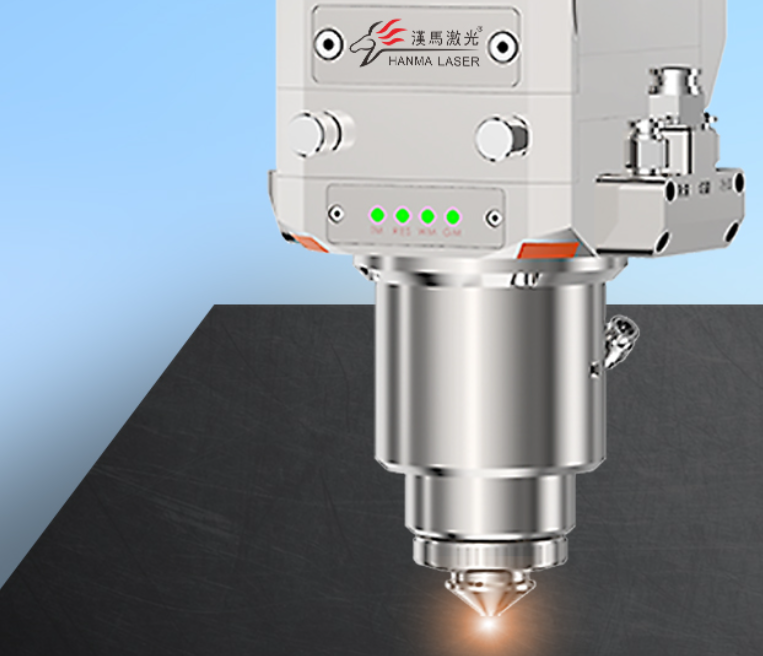

During the cutting process, a special lens focuses the laser beam onto the workpiece, allowing it to be precisely focused. The narrowest part of the beam is less than 0.0125″ in diameter for ultra-sharp cuts. Additionally, kerf widths can be as small as 0.004 inches, depending on the thickness of the material being cut. Perforations are made after each cut, which involves a high-powered laser beam. The piercing process is relatively quick, taking only 5 to 15 seconds on 13mm thick stainless steel.

Reliability

Reliability is an important factor in the metal laser cutting process. A reliable machine should be able to maintain the orientation and parallelism of the cut parts. The precision of the metal laser cutting process depends on the precision of the helical racks and guides.

When using a metal laser cutter, it is important to ensure that the material being cut does not contain flammable lubricants, oils or explosives. This is to avoid any personal injury.

Cost

The cost of metal laser cutting depends on the material you need to cut and the time required for the cutting process. The length of time depends on the size of the work, the thickness of the material and the number of carvings. Most services are charged by the minute, which means the longer the machine runs, the higher the cost. Other services may be charged by the centimeter, reflecting the amount of work involved in the process.